A Guide for Warehouse Operations Directors & Managers

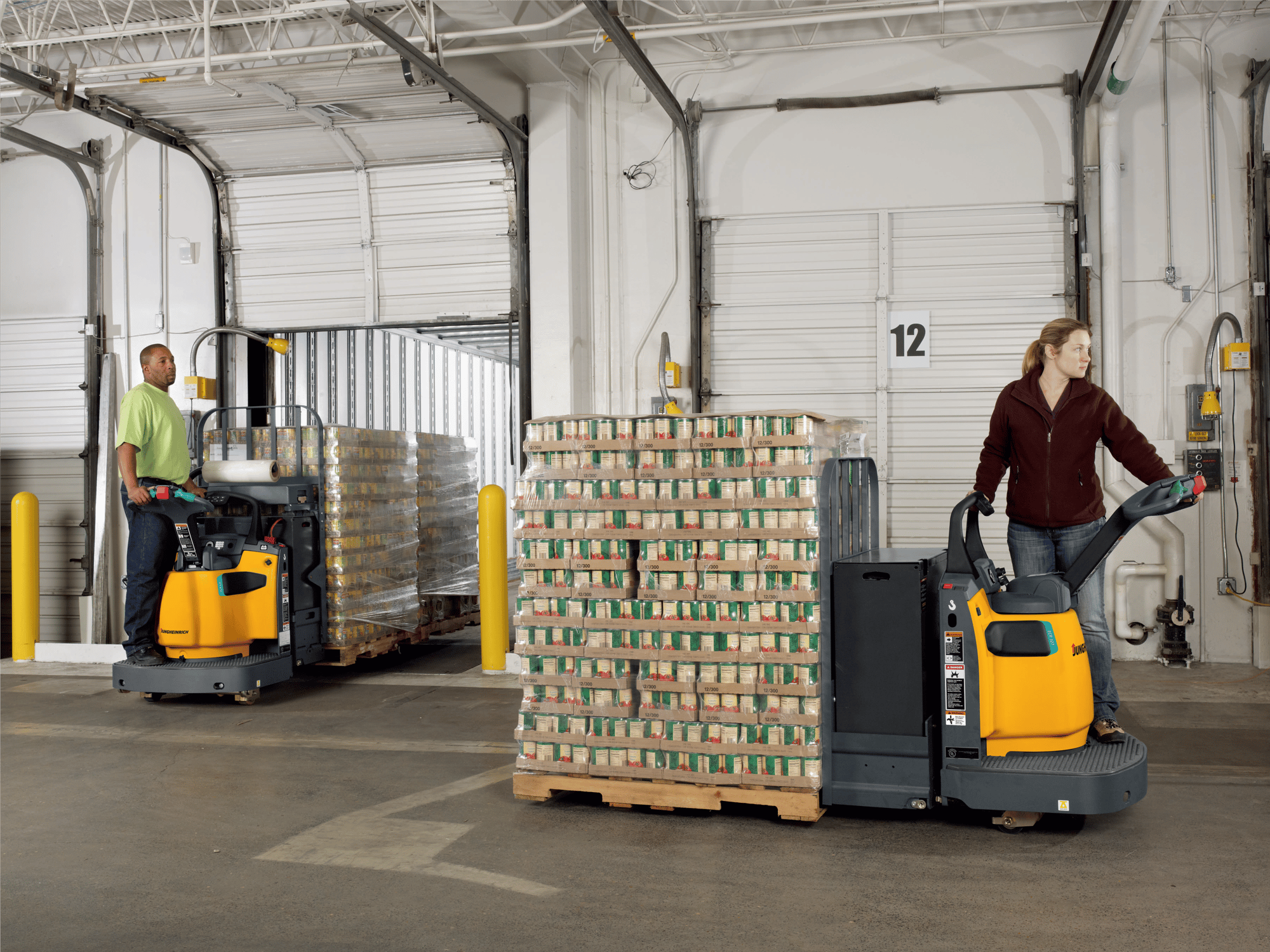

As throughput demands continue to soar, reliance on manual or electric walkie pallet jacks may be limiting your warehouse's full potential. For many operations, the electric rider pallet truck (or ride-on jack) is often viewed as a luxury— only a step below a full forklift. In reality, it’s a crucial piece of material handling equipment that serves a unique and often necessary role in high-volume logistics.

Here are some key indicators that signal your operation has reached the tipping point, and you stand to gain significant efficiency, ergonomic, and safety benefits by transitioning to electric rider pallet trucks.

1. The Distance Tipping Point: When Pushing Becomes Wasted Time

One of the greatest justifications for investing in a rider jack is distance. A manual or electric walkie jack requires operators to walk the entire time they’re transporting goods. This works fine for short distances, but it quickly becomes a bottleneck and a major source of fatigue for long-haul tasks.

- The Threshold: If your operators are routinely traveling more than 100 feet (30 meters) with a pallet load (especially one up to 8,000 lbs), the rider jack becomes a must-have.

- The Benefit: A walkie jack travels at a walking pace (approx. 3–4 mph). A rider jack can achieve speeds of 6 mph, effectively doubling your travel speed over long distances. This translates directly to increased trips per shift and higher overall throughput.

2. The Volume Tipping Point: High-Cycle Operations

The cost of a rider pallet truck is also justified when it’s continuously engaged in high-volume tasks that directly impact your delivery schedule.

- Dock-to-Staging: Are you moving high volumes of inbound or outbound pallets from the receiving dock to a distant staging area?

- Mass Order Picking: Are your team members performing extensive, full-pallet moves for case picking or large-volume replenishment?

- The ROI Factor: If the equipment is idle for long periods, stick with a walkie. If it is running non-stop for 4+ hours of an 8-hour shift, the efficiency gains from the rider jack will quickly pay back the initial investment.

3. The Ergonomics & Safety Tipping Point: Fatigue is a Hidden Cost

While electric walkie jacks eliminate the strenuous pushing and pulling of a manual jack, they don’t eliminate the strain of continuous walking. Fatigue is not just an operator comfort issue; it’s a serious drag on productivity and the leading contributor to accidents.

- Mitigating Fatigue: On long routes, an operator walking behind a walkie jack will naturally slow down as the day progresses. The rider jack allows the operator to stand on a cushioned platform, maintaining a high, consistent speed throughout the entire shift.

- Reducing Liability: Reduced physical strain dramatically lowers the risk of muscle and joint injuries related to repetitive movement, directly impacting your worker's compensation claims and long-term operating costs.

4. The Control Tipping Point: Mastering Ramps & Docks

Moving heavy loads on an incline requires sophisticated braking and control, which basic walkie jacks may lack.

- Superior Braking: Rider jacks are equipped with advanced braking systems (often electric/regenerative) designed for high-speed use and large loads. This provides superior control and stability, making them significantly safer when navigating dock plates, low-grade warehouse ramps, or bridge plates into trailers.

- Visibility and Stability: On an end-rider jack the operator is positioned for better forward visibility at speed, enhancing safety in busy dock areas and throughout fast-moving warehouses.

Is it Time to Invest?

Ask yourself these three questions:

- Is the average travel distance for my heaviest pallet moves greater than 100 feet?

- Are we struggling to meet productivity targets in our high-volume staging or receiving zones?

- Is operator fatigue from non-stop walking a visible issue contributing to slowdowns or safety concerns?